Process

Consistent plant engineering with COMOS Process.

COMOS – Making data work.

The product range of COMOS Process includes integrated software solutions for process engineering. At an early stage of plant design, layout data can be used to create process flow diagrams that form the basis for the more precisely defined piping and instrumentation diagram. Intelligent rules serve to identify any inconsistencies early on in the project so that errors in the downstream engineering process can be avoided. COMOS Process supports quality-controlled pipe engineering and pipe spec management conforming to international industry standards. Translation of process data on the geometric level in the form of isometrics and 3D images is easy to derive.

COMOS FEED

One of the most important tasks of the front-end engineering & design (FEED) phase is an initial cost calculation and a clear representation of processes. COMOS FEED provides the basis for the initial rough calculation, even in this early engineering phase. Processes can be displayed transparently in block diagrams. Entire process sequences, flow directions and the relationship between the different processes can easily be represented in these diagrams.

COMOS P&ID

Fast and easy generation of Piping and Instrumentation Diagrams with COMOS P&ID.

Multiple departments are involved in basic and detail engineering. Since there is a particularly significant risk of data loss at the interfaces - especially at the transitions between process, pipe and EI&C engineering - data and information from the FEED phase can be seamlessly integrated into COMOS P&ID.

COMOS Pipespec

Safely defining and managing pipes with COMOS PipeSpec.

The versatile pipe parts catalog in COMOS PipeSpec Designer allows quick and quality-assured pipe spec construction based on internationally validated standards. Using parameters such as material, pressure and temperature, components can be selected from a multitude of options and classified in pipe specs. You can also attach generic, configurable description texts for parts lists, order lists, etc to the pipe specs to get a better overview. If pipe part attributes are to be changed, the respective pipe spec is automatically updated using an inheritance mechanism. Furthermore, the object orientation ensures consistent pipe spec use across all departments and disciplines.

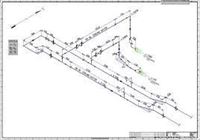

COMOS Isometrics

Interactive generation of isometrics from construction to as-built status with COMOS Isometrics.

With COMOS Isometrics, a complete solution is now available for interactive isometry creation based on a central database. Multiple interfaces allow for trouble-free exchange with common third-party systems and data formats. Engineering projects such as planning new plants, reconstruction planning, inventories and inspections can be implemented easily and with consistent data.